Low carbon concrete

Concrete evolution - engineered solutions for construction

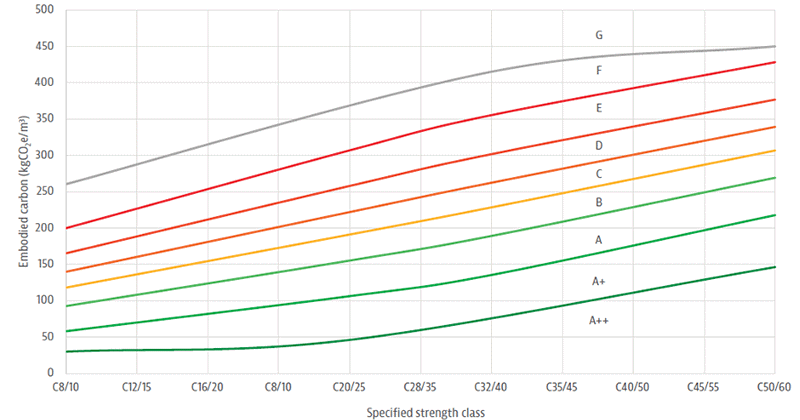

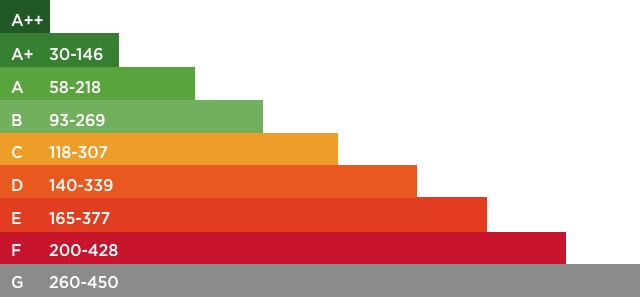

What concrete carbon rating do you want to achieve?

Tarmac has made it easy for customers to make more sustainable choices in concrete specification, we’ve made low carbon concrete selection simple. Tell us what rating you want to achieve from industry standard A++ to G and we will supply the right concrete for your project requirements.

We have aligned our low carbon concrete supply to the ICE, Green Construction Board Low Carbon Concrete Routemap ratings. This means all you need to do is ask for CEVO concretes, tell us the carbon reduction percentage you want to achieve, and we’ll engineer the right low carbon concrete solution.

Simple. Strength + CO2 reduction = low carbon concrete

Lower carbon concrete - the future of design

Think - How much carbon do you want to cut and what are you building?

CEVO engineered low carbon concretes will deliver.

Advancing progress in the materials science of low carbon concrete

Low Carbon solutions made simple

Industry aligned low carbon/Net Zero concrete supply

How we calculate the carbon in our concrete

Engineered low carbon concretes for infrastructure.

Calculate your low carbon concrete footprint

The concrete carbon tool provides carbon footprints, created to PAS 2050 methodology, using Tarmac average data, benchmarked against the Green Construction Board LCCG benchmark.

Cutting carbon end to end

To truly advance carbon reductions we feel that we need look at every aspect of our manufacture and supply to support real progress towards Net Zero.

Tarmac and its parent company, CRH, has an ambition to reach net zero by 2050.

CRH has set an industry-leading target to reduce absolute CO2 emissions across the Group by 30% by 2030 (from a 2021 baseline). The Science Based Targets initiative (SBTi) has validated CRH’s near-term science-based carbon emissions reduction targets in line with a 1.5°C pathway.

So, it's not just our materials that are cutting emissions.

All electricity used in manufacture is renewable

Use of transition fuels such as hydrotreated vegetable oil (HVO)

Transitioning mobile plant to electric

We are collaborating to drive innovation and are proud to have developed and launched the first electric concrete mixer in the UK.

Supply chain engagement through our Decarbonisation Club and Innovation Challenge

Low Carbon Concrete performance benefits

CEVO Low carbon concrete is a type of concrete that is designed to minimise its carbon footprint during its production.

Here are some performance attributes of our CEVO low carbon concrete:

Realtime monitoring and AI predictions of concrete strength & temperature

What is Low Carbon Concrete?

Low carbon concrete is a type of concrete that uses alternative materials or processes to reduce its carbon footprint.

35% Carbon Reduction

National Rehabilitation Centre

CEVO evolution

Low carbon concrete (LCC) is the term given to the latest design concretes that are progressing concrete’s transition towards Net Zero targets. Following years of trials and advances in concrete technology CEVO low carbon concretes deliver simple solutions to making better material choices.

CEVO concretes offer low carbon alternatives to traditional concretes.

CEVO is our commitment to supplying concretes that offer transparent carbon savings and easy to understand performance grading based on the amount of carbon taken out of the design using replacements, limestone fillers or an Alkali Activated solution.

We align our current range of CEVO, low carbon concretes, to ratings published by the ICE, endorsed by the Green Construction Board in the Low Carbon Concrete Routemap. A, B, C to G gradings similar to efficiency bars that we see on electrical items across our daily lives.

Using this system to select the carbon reduction required means as new materials science offers improved new low carbon concretes, we simply align the product to the grading system. Low carbon concretes made simple.

The past present and future of concrete’s Net Zero transition

30 years of progress - 38% reduction in CO2 per tonne of product. How did we get there?

1990

Past

Present

Low Carbon Concrete

- Portland Limestone Ternary

- Composites Alkali Activated

- Cementitious Materials

Fly Ash / GGBS availability in UK

- Calcined Clay