Low carbon concrete - Pioneering the evolution of concrete

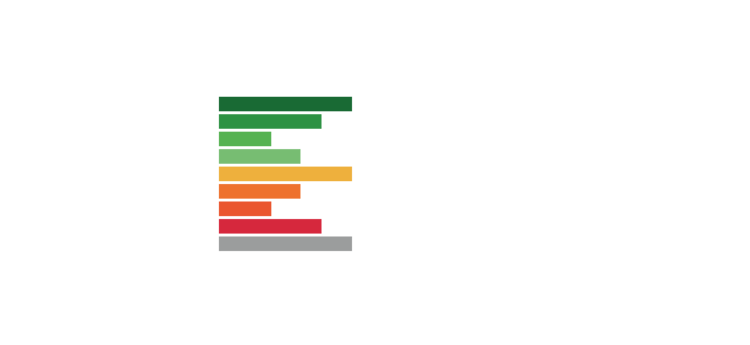

Transparent CO2 reduced concrete specification

At Tarmac, we are committed to progressing the decarbonisation of concrete supply. And as the materials science evolves over the next few years, we believe it is vital to assist our customers to make more sustainable concrete specification choices. That’s way we have simplified the process of choosing more sustainable, lower carbon concrete. Just let us know your desired industry-standard rating, from A++ to G, and we'll provide you with the perfect concrete solution for your project. Engineered to meet your application performance criteria.

Aligned with Sustainability Ratings

We've aligned our low carbon concrete supply with the ICE (Institution of Civil Engineers) Green Construction Board Low Carbon Concrete Routemap ratings. That means all you need to do is ask for CEVO concretes, specify your carbon reduction target, and we'll engineer the ideal low carbon concrete solution.

The Future of Sustainable Design

As cutting-edge materials science advancements shape the landscape of concrete design, we apply these innovations across the sustainability spectrum. Simply tell us your desired carbon rating, and we'll supply a solution, incorporating the latest alternative materials, such as limestone fillers and alkali-activated solutions.

Advancing progress in the materials science of low and lower carbon concrete

Think how much carbon do you want to cut from your concrete and what are you building? CEVO engineered low carbon concretes will deliver.

Reduced carbon footprint

Low carbon concrete is specifically designed to minimize carbon dioxide emissions during production through the use of alternative materials.

Durability

Our low carbon concrete can be tailored to be just as robust and long-lasting as traditional concrete, making it an indispensable choice for construction materials.

Strength

Low carbon concrete can deliver comparable strength to traditional concrete, depending on the specific mix design and intended application.

Versatility

Our low carbon concrete can be applied in a wide array of uses, including structural and non-structural applications, paving, and decorative purposes.

Widespread Availability

With the increasing demand for sustainable building materials in the UK, low carbon concrete options are becoming more readily accessible.

Low carbon floor screeds

87% lower carbon emissions

Lightweight construction

Tarmac CEVO low carbon concrete - accredited CPD sessions now available