Sustainable Roads from Pave

Using technology for more sustainable road resurfacing

Using the latest paving technology, Tarmac Contracting is leading the way in building better road surfaces, that last longer, in less time while generating fewer carbon emissions.

Experience and technology developed while surfacing some of the world's leading motor racing circuit and test tracks, is now being used to build better roads.

Our latest solutions in process and programme modelling are available now. They deliver immediate results. The latest generation of digital applications allow both client and contractor to reduce all elements of the process.

• Cut programme time and associated costs

• Optimise designs to reduce carbon

• Improve ride quality

• Implement fast installation paving

Pave offers solutions to everyday surfacing challenges.

Precision, efficiency, productivity, and sustainability. The suite of technology has been proven across the UK to deliver against varied and specific programme demands.

Talk to us about PAVE

Biogenic and Long-life asphalts - advanced asphalt materials technology for road surfacing

Working with our supply partners, Tarmac are developing and trialling a new generation of low carbon, biogenic and long-life asphalts. This technology will help reduce carbon footprints, capture carbon and significantly extend pavement life compared to current materials.

Biogenic asphalt binder technology effectively locks away carbon absorbed during the growth of the biomass element, turning the road into a carbon sink. Since the asphalt can be recycled at the end of the pavement life, most of this carbon will not re-enter the atmosphere. According to available data, biogenic asphalt technology could potentially reduce the carbon footprint of a typical asphalt mix by approximately 40%. This helps our customers on their path towards net zero.

1. Using lower carbon materials

Tarmac is working hard to encourage adoption of lower carbon asphalt and concrete technology. Progress has already been made with over 4 million tonnes of Tarmac warm mix asphalts being laid on UK roads since 2014, but more needs to be done.

In August 2021 National Highways officially requested that everyone involved in the construction and maintenance of the strategic road network, particularly designers and main contractors, use warm mix asphalts as their default surfacing material to help move towards its net zero objective.

We recently announced another significant commitment to reducing both our own and our customers’ carbon footprint. We will now be supplying only ULTILOW warm mix asphalts for delivered base and binder courses and all surface course materials except for modified binder materials and HRA with a stone content mix of 35% or lower. This is expected to save around 21,000 tonnes of carbon dioxide per year – the equivalent of around 34,000 flights between London and New York.

2. Using more recycled content and working towards a circular economy

One of the benefits of asphalt as a surfacing material is that it is recyclable. Once an old road surface is planed out in can be used in the construction of new roads.

Tarmac are investing in a new generation of asphalt plants like our state-of-the-art Birmingham Asphalt Plant that can incorporate higher levels of RAP content into asphalt mixes, for improved sustainability.

We are also leading the way in materials innovation that incorporates other secondary materials like steel slag aggregate and rubber from end-of-life car tyres into asphalt mixes, while maintaining or even enhancing performance.

Using more recycled content - from road building

How can asphalt planings be recycled?

Asphalt is already one of the world's most recycled construction materials. Tarmac are investing in a new generation of asphalt plants that can incorporate higher levels of reclaimed asphalt planings (RAP) into asphalt mixes for improved sustainability. This includes our state-of-the-art Birmingham Asphalt Plant located next to the M6 and ideally placed to support the Midlands Engine for Growth and our Harper Lane Asphalt Plant in Hertfordshire, serving Greater London.

However planings can also be recycled by mobile plant. In a highly controlled process, RAP is crushed and screened for consistency, then combined with additional aggregate, foamed bitumen and a hydraulic cement or lime binder.

How does foam mix asphalt recycling technology make roads more sustainable?

Using proven foamed bitumen and cold paving technology, road arisings can be processed and used in sub-surface reconstruction. As a result, it offers savings in both transport and disposal costs. ULTIFOAM recycled foam mix asphalt can be used as base and binder course in both new road construction and road maintenance. It provides safe encapsulation of tar contaminated road planings that are excluded from hot mix asphalt recycling and would otherwise be considered a hazardous waste requiring costly, specialist disposal. It also offers major environmental benefits from reductions in the use of energy and primary aggregates. This allows local authorities to recycle asphalt planings from their road network and use them elsewhere in road reconstruction. This improves sustainability and reduces disposal costs.

What else can I do to make my road more sustainable?

Warm mix asphalts can be combined with recycled and secondary materials like end-of-life tyres.

Closed-loop road recycling with Rutland County Council

ULTIFOAM

1750 tonnes of tar bound planings recycled and re-used

Our transition to a circular economy

FIND OUT MORE

Read about Resource Efficiency on our sustainability report website

Using more recycled content - from other waste streams

What is rubber modified asphalt?

Tarmac’s Ultipave R and Rubber Modified Asphalts are warm mix stone mastic asphalt that incorporate recycled rubber from end-of life car tyres. This helps to recycle some of the 40 million waste tyres generated every year in the UK.

For major trunk roads and motorways, ULTIPAVE R is now available as a rubber modified thin surface system, with BBA HAPAS Clause 942 approval for use on the strategic road network.

How do rubber modified asphalts make roads more sustainable?

Tarmac’s Ultipave R and Rubber Modified Asphalt use warm mix asphalt technology to achieve a lower carbon footprint, typically 8% lower than the equivalent conventional SMA. The use of recycled rubber crumb in the mix helps to avoid export of waste car tyres, incorporating approximately 750 tyres per kilometre for a typical single lane road.

Examples of using rubber modified asphalts to make roads more sustainable

Using our innovative Rubber Modified Asphalt to resurface the A426 in Leicestershire enabled the rubber from around 3500 tyres to be recycled and saved 14 tonnes of CO2 emissions.

What else can I do to make my road more sustainable?

Rubber modified asphalts can be combined with recycled and secondary materials like RAP and steel slag aggregate for an even more sustainable solution.

How can using steel slag aggregate make roads more sustainable?

Steel Slag aggregate is a secondary aggregate produced by the steel industry. The shape, hardness and heat retaining properties of steel slag aggregate make it an ideal material for use in asphalt, enabling good compaction and delivering excellent durability. Tarmac source steel slag aggregate from our facility at the steel works in Port Talbot, South Wales and transport it by rail, helping to make it a very sustainable material for road building.

3. Using less material, avoiding waste and reducing transport emissions

Making more efficient use of materials

How do thin surface course asphalts help make roads more sustainable?

Using thin surface course materials can improve sustainability of road resurfacing. Inlays using high performance asphalts, can offer an alternative to full depth reconstruction. This helps to reduce the depth of plane out required, the volume of asphalt used and the associated emissions from inbound and outbound transportation required.

Balanced use of high PSV stone for road building

The high PSV stone used to surface roads is a valuable resource. Hardstone quarries naturally produce a range of aggregate sizes in certain proportions. Using more 6mm, 14mm and 20mm asphalts helps to balance out high demand for 10mm aggregate for use in stone mastic asphalts (SMA’s) and surface dressing. The larger stone the stone size, the less secondary crushing required and the less stone is lost to dust.

This makes use of 14mm and 20mm asphalt surface courses more sustainable choices, where appropriate, helping to achieve a long-term balance in supply and demand for high PSV stone. One option is Ultipave Single Layer, a BBA HAPAS accredited 20mm asphalt designed for deeper single layer road reconstruction.

Reducing wasted asphalt from highways maintenance

How can we reduce waste from highways maintenance?

Using exactly the right quantity of asphalt material and extending the workability of asphalt materials can help reduce wasted materials from pothole repairs and road reinstatements.

How do site mixed asphalts make roads more sustainable?

Our award winning Ultipatch Sitemix asphalts, developed specifically for use with mobile asphalt batching plants, provide exactly the right quantity of fresh site mixed asphalt. As a result, they help to reduce waste from highways maintenance operations for a more sustainable approach. This innovative product won Highways Industry Product of the Year at the Highways Awards 2018.

Sustainable Contracting

How can we make highways maintenance more sustainable?

Tarmac Contracting are now using logistics and business process optimisation (BPO) technology to make highways maintenance activities more sustainable. This technology allows accurate tracking of materials from the plant to the site and was used recently during the resurfacing of the Silverstone Motor Racing Circuit.

How does BPO technology help make road building more sustainable?

Carbon emissions are minimised by making sure that exactly the right quantity of asphalt is supplied to the site, avoiding over-production and wasted material. Excess vehicle emissions are reduced by minimising vehicle movements and waiting times. Making sure that materials arrive at the optimal paving temperature also helps improve compaction, finish and the quality of joints. This helps to extend pavement life and avoids future maintenance to reduce long term carbon emissions.

Carbon conscious programme delivery

The recent A11, Thetford to Attleborough scheme in Norfolk was delivered in a carbon conscious and sustainable way, with carbon emissions systematically calculated throughout the project delivery. A number of materials and contracting decisions were made to reduce carbon emissions. This included using a warm mix asphalt binder and surface course in place of conventional hot mix asphalt and increased reclaimed asphalt planings (RAP) content. This helped to offset any additional carbon emissions from the SAMI layer and still deliver a 14% reduction in CO2 emissions on materials. Further reductions in CO2 emissions were achieved by ‘back-hauling’ road planings for recycling at Tarmac’s plants, using empty asphalt trucks. This delivered a 46% reduction in transport emissions.

Total project saving of 1,154 tonnes of CO2 emissions, a 20% reduction compared to the original plan.

Sustainable Contracting

Extending the life of asphalt overlays on concrete based roads

4. Building roads that last longer and extending pavement life

Making the right choice of material is particularly important on challenging roads that are subject to repeated cracking because of underlying movement in the pavement. This can include evolved roads, roads in areas with clay soils subject to seasonal expansion and contraction and roads based on jointed concrete that can be subject to thermal and traffic induced movement.

By adopting a whole life approach and investing in better materials and highways engineers can break the cycle of repeated deterioration and running repairs which can be costly in terms of maintenance budgets and carbon emissions.

Improving durability and crack resistance

What makes asphalt more crack resistant?

Modern high-performance asphalts which have been developed specifically to offer enhanced resistance to reflective cracking and road surface deformation. These products include a high-performance Polymer Modified Binder and selected aggregates, to enhance deformation resistance, for a longer lasting surface.

How do polymer modified, crack resisting asphalts make roads more sustainable?

By extending pavement life, polymer modified, asphalts extend surfacing intervals and reduce the materials and operational emissions associated with maintenance interventions. As a result they help reduce whole life costs.

Using an asphalt SAMI (stress absorbing membrane interlayer) can also extend the life of asphalt overlays on concrete based roads.

Age defying asphalts

Tarmac are now working with key industry partners in a new generation of asphalts that show far less deterioration from oxidation and loss of volatile oils and also less cracking or deformation from the stresses generated by traffic loading.

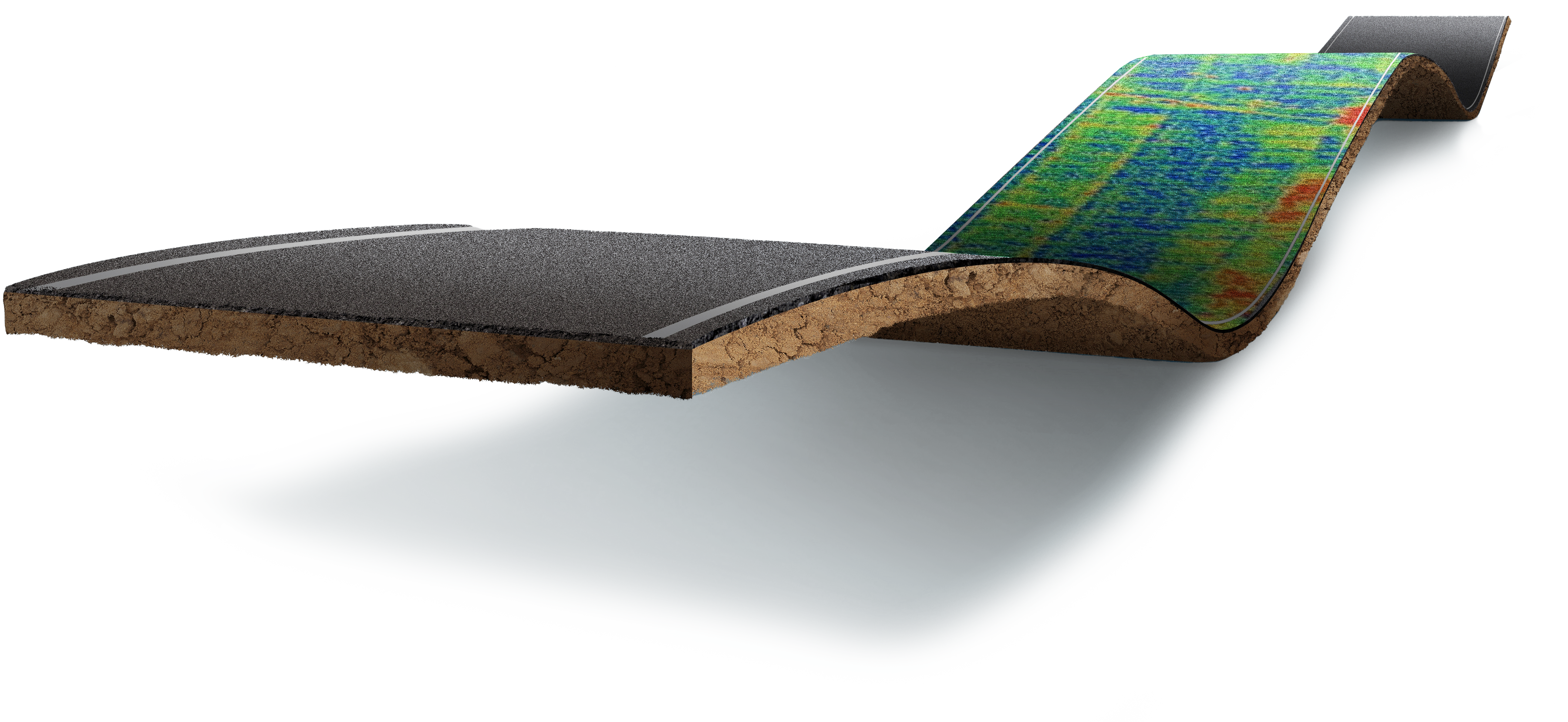

Using technology to optimise asphalt mix for the weather conditions

Getting paving right first time is essential to building sustainable roads. Tarmac is pioneering the use of technology that uses site specific data and our materials expertise to tailor the specified asphalt to best fit conditions whilst optimising the material workability. This improves compaction and finish to help roads last longer.

5. Building better environments

Making quieter, safer roads

Asphalt for quieter residential roads

Tarmac’s ULTIFLEX asphalt delivers a smooth, negative texture making it one of the quietest hard-wearing surfaces available. Perfect for residential streets. ULTIFLEX is also available as a warm mix asphalt with a reduced carbon footprint.

Cleaner air and reduced fumes

Improving air quality when resurfacing roads

Warm mix asphalts reduce site fumes by approximately 90%, improving air quality for site workers and helping to meet clean air targets.

Encouraging more sustainable forms of transport

Building brighter, safer cycleways

ULTICOLOUR coloured asphalts are helping to build the next generation of visually distinctive and safer cycleways to encourage more people to choose cycling as a regular means of transport. Delivering clear visual demarcation and a smooth, finish helps to enhance safety for cyclists and pedestrians.

Sustainable Rail Transport

With more than 60 rail-connected sites across the UK, Tarmac are one of the country’s biggest users of the rail freight network, transporting around nine million tonnes of materials every year. This extensive use of rail transport helps to avoid thousands of heavy goods vehicle journeys and eliminate the associated carbon emissions.

6. Tarmac’s commitment to sustainability

Responsible sourcing

Our commitment to providing sustainable solutions is also demonstrated by our certification to BES 6001 the framework standard for Responsible Sourcing, across our entire product range at “Excellent” standard.

These certificated can be found on our website.

Sustainability report

Sustainability is about securing long-term success for our business, customers and communities by continually improving environmental, social and economic performance throughout the whole life cycle of our products, services and solutions.

Carbon footprint

Calculating the CO2 footprint for a product not only provides a clear understanding of the products that are being used but also allows for carbon to be managed in the supply chain. It is also possible to compare alternative products and services, actively seek lower carbon alternatives and understand the impact of using recycled and secondary materials

Solution guides

Our solution guides encompass all parts of our business including Aggregates and Asphalt, Building Products, Cement, Lime and Powders and Ready Mixed Concrete and wider aspects of sustainable construction such as whole building approaches and sustainability certification schemes. The guides provide an improved understanding of how products and solutions we produce can be used to deliver a better, more sustainable built environment.

Our 'whole life' approach to continually improve sustainability